"TRUE SUSTAINABILITY IS IN THE DETAILS"

In a world where the decorative hardware industry has been stuck for decades in the mire of model replication and planned obsolescence, a silent change has begun. It's led by Mr. Driss Massanou, a surface coating expert with over 25 years of experience. He observed the industry's dysfunctions and realized that the smallest, most overlooked components held the key to a truly sustainable product. This awareness, born from an obsession with detail, became the foundation for a new approach. It was this deep conviction that pushed him to master eco-friendly coating technology and establish the complete production chain for his first sustainable product: dima handle, the world's first decorative hardware brand built on the principle that true sustainability is in the details.

A BROKEN SYSTEM

Today, the decorative hardware industry is built on a flawed premise: more is better. Manufacturers' catalogs overflow with hundreds of models, creating an illusion of choice. This overwhelming variety is then pushed down the supply chain to resellers and showrooms, who are forced to manage complex, constantly changing collections.

But this system is fundamentally broken. To offer such a wide range of products, most manufacturers rely on a chaotic and fragmented network of subcontractors for every stage of production. This fragmentation, driven by the obsession with quantity over quality, has disastrous consequences for everyone, including our reseller partners:

- Inconsistent Quality: With multiple subcontractors, achieving a standard quality for details like color and finish is impossible.

- Constant Delays: Each extra step in the chain adds risk and extends delivery times.

- High Costs: Inefficiency and a lack of automation drive up production costs.

- Zero Innovation: The focus remains on replicating models, not on genuine improvement.

The result is an industry that prioritizes superficial variety over true excellence. This can only be fixed by a radical transformation at the source: the production itself.

THE TOXIC REALITIES

The greatest tragedy of this system lies in the devastating effects of its neglected details on human health and the environment.

Toxic Polishing Processes

Impossible to automate, exposing workers to metallic nanoparticles.

The Toxic Cocktail of Electrolytic Plating

This outdated process involves submerging hardware in a chemical bath of heavy metals, including allergenic Nickel and carcinogenic Chrome (a Class 1 carcinogen, WHO). This method produces a product coated in toxins and creates highly contaminated industrial sludge.

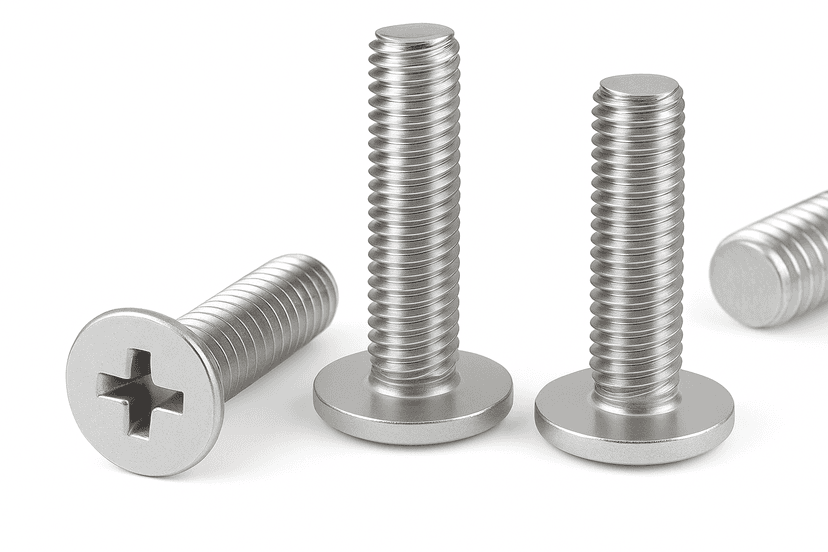

THE POISONOUS SCREW

The clearest proof that true sustainability is in the details lies in a component engineered to fail: the screw.

The market is flooded with cheap steel screws, hastily plated with Nickel, Chrome, or Zinc. This is not an accident; it's a strategy. Each screw becomes a poisonous hive installed directly into our homes. A single kitchen can contain over a hundred.

The consequences are inevitable:The cheap plating wears off, the steel rusts, and a toxic dust containing flakes of allergenic Nickel and carcinogenic Chrome contaminates your clothes, food, and air. This corrosion also produces foul metallic odors and can leach chemicals onto your belongings.

Once rusted, these screws cannot be recycled. They become permanent hazardous waste.The industry has turned a simple screw into a weapon of planned obsolescence.This is the real cost of ignoring the details.

THE DIMA HANDLE SOLUTION

Faced with this bleak picture, we chose a different path. Instead of multiplying flawed models, we focused on perfecting every single detail of one timeless design: the stainless steel bar pull.

Our solution is built on a new philosophy for the industry, inspired by the Slow Fashion movement.We call it the Slow Accessory Philosophy. This is a commitment to quality and durability over cheap, disposable products. While other brands chase new models, we focus on perfecting the core product, offering trends only in coatings and colors. Our production process has no melting, no molds, and no high emissions. Unlike the fragmented traditional industry, our integrated, fully automated production guarantees consistent quality and efficiency, making us a fast and reliable partner.

This philosophy is also a Revolution of Values. We believe new generations of consumers deserve authenticity and real value. Dima Handle meets this expectation by offering the highest quality, born from an obsession with detail, at the fairest price.

This approach is brought to life through tangible innovations, starting from the inside out.

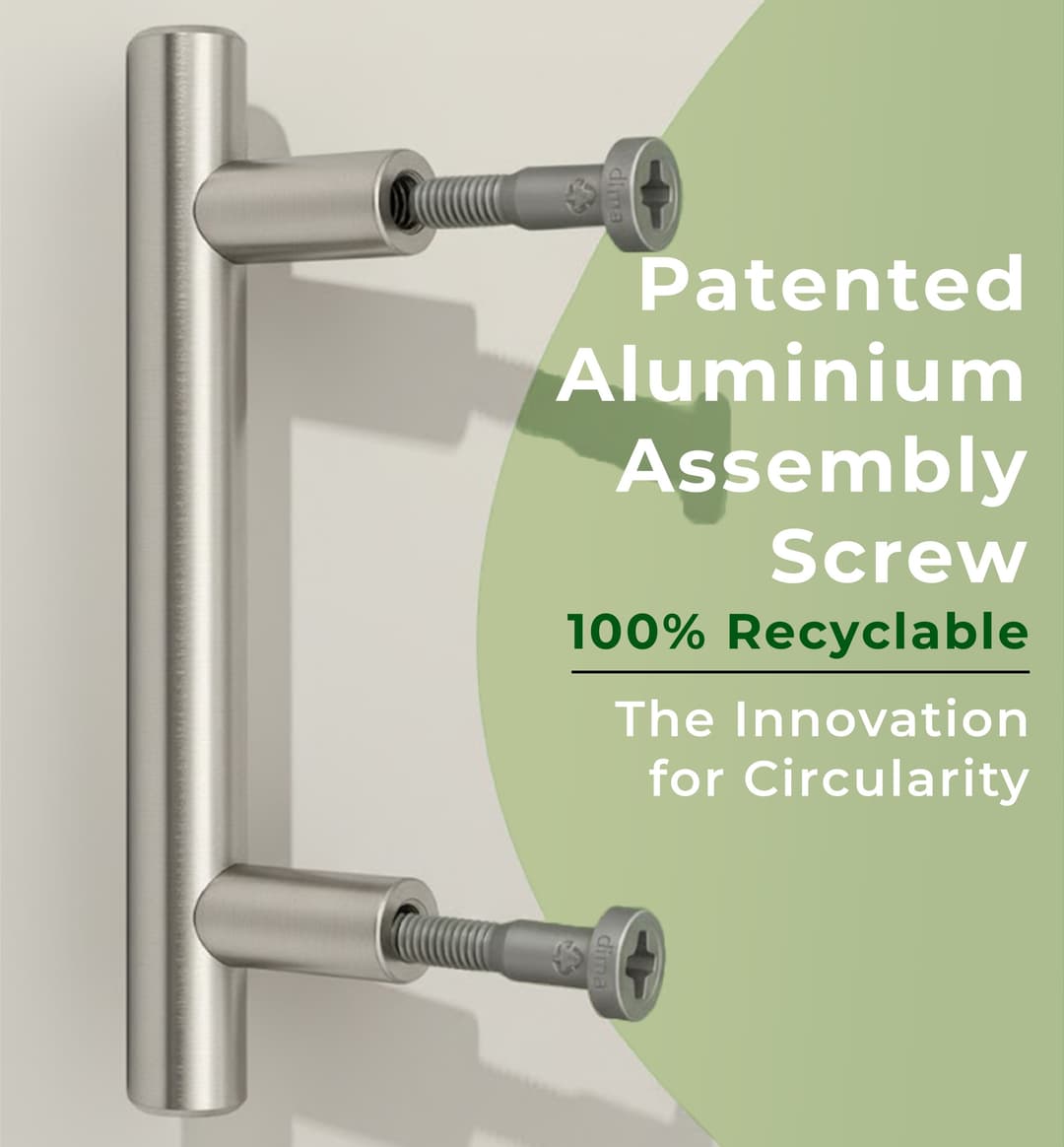

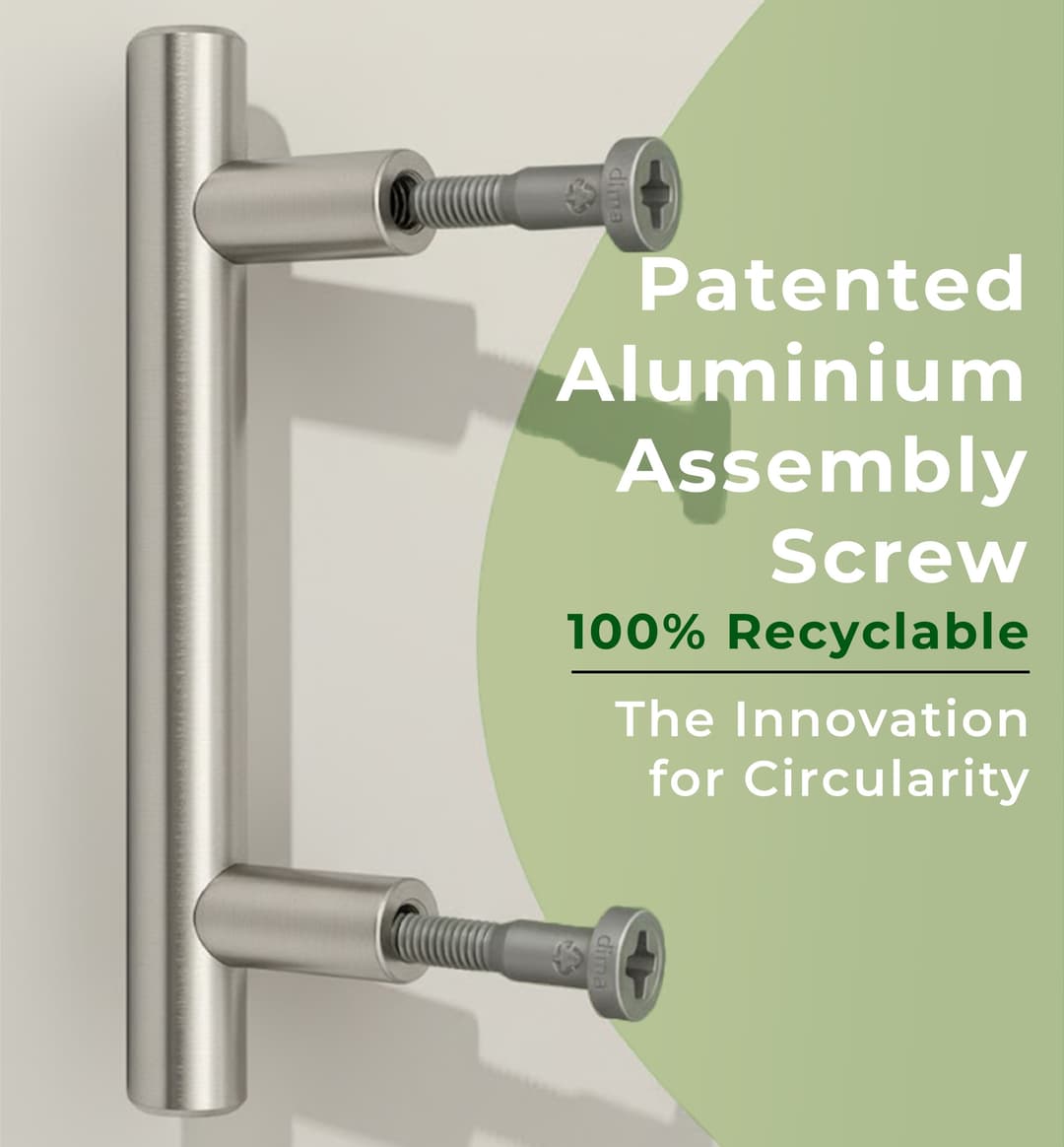

The Internal Assembly Screw

Our revolution begins with a detail most manufacturers ignore because it's hidden: the internal screw that holds the handle together. While others use a cheap steel screw prone to corrosion, we developed and patented a specialized, aerospace-grade aluminum assembly screw. Its unique treatment ensures it will never loosen or corrode.

We perfected this invisible component because, for us, true sustainability leaves no detail behind.

The Mounting Screw System: A World-First in Convenience and Durability

Next, we tackled the screws you can see. We are the first and only manufacturer in the world to provide 100% aluminum mounting screws, guaranteed against corrosion for the life of the product. But we didn't stop there. With every handle, we provide four screws, not two: a pair of 25mm and a pair of 45mm screws. This ensures our handles can be installed perfectly on any cabinet or drawer,

regardless of thickness, without the end-user needing to search for another screw.

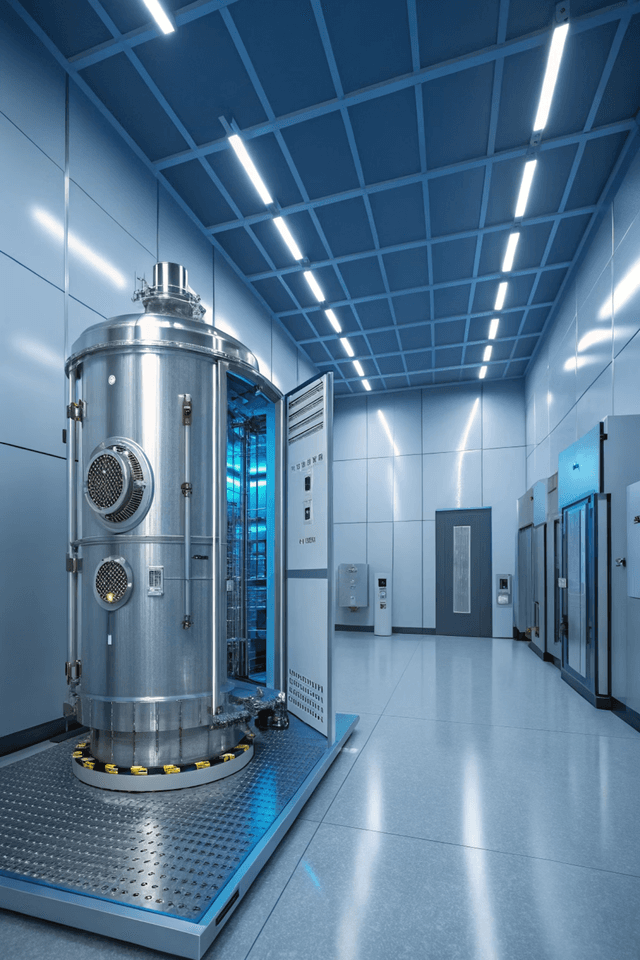

The PVDuv Revolution – When Innovation Meets Ecology

The technological heart of this revolutionary transformation is called PVDuv (Magnetron Sputtering + UV Varnish Protection). The product of years of R&D, this technology provides a single solution to the chronic problems of the traditional industry.

The PVDuv process works on a completely different principle from electrolytic plating. Instead of toxic chemical baths, atoms extracted from noble metal targets using the magnetron sputtering method in a vacuum environment are deposited as an ultra-thin film layer onto the stainless steel surface. Then, this precious layer is protected with a special UV varnish.

This advanced technology is a complex process that requires serious investment and deep expertise. Fully automated production systems ensure consistent quality and repeatability. The dima handle team, with its years of R&D experience, has achieved perfect mastery of this technology and guarantees the same high standard in every product.

The Proof

Our commitment is not just a story; it's backed by a lifetime structural guarantee and proven by rigorous, independent laboratory tests.

Measurable and Certified Details

We certify our quality with leading industry standards, including:

ISO 9227

Extreme corrosion resistance certification.

Solvent Rub Tests

Chemical durability verification.

SGS Certifications

100% Heavy Metal-Free, including Nickel and carcinogenic Chrome VI.

The full details of our testing and certifications are available for review. This is what we mean by total transparency.

The Result: An Economic and Environmental Advantage

Long-Term Savings

A quality product built to last for 15+ years means significant long-term savings for consumers and businesses alike.

Minimal Impact

Durability translates directly to minimal environmental impact, reducing waste and the need for replacement.

This obsession with detail transforms the consumer's economy.

Our Mission

Our Mission is to help all our clients complete their production with guaranteed sustainable and eco-friendly articles.

We position ourselves as the partner brand for 'green, safe, sustainable, circular' hardware, offering a single product that meets all tastes and ensures our partners can complete their production with a healthy and reliable accessory.

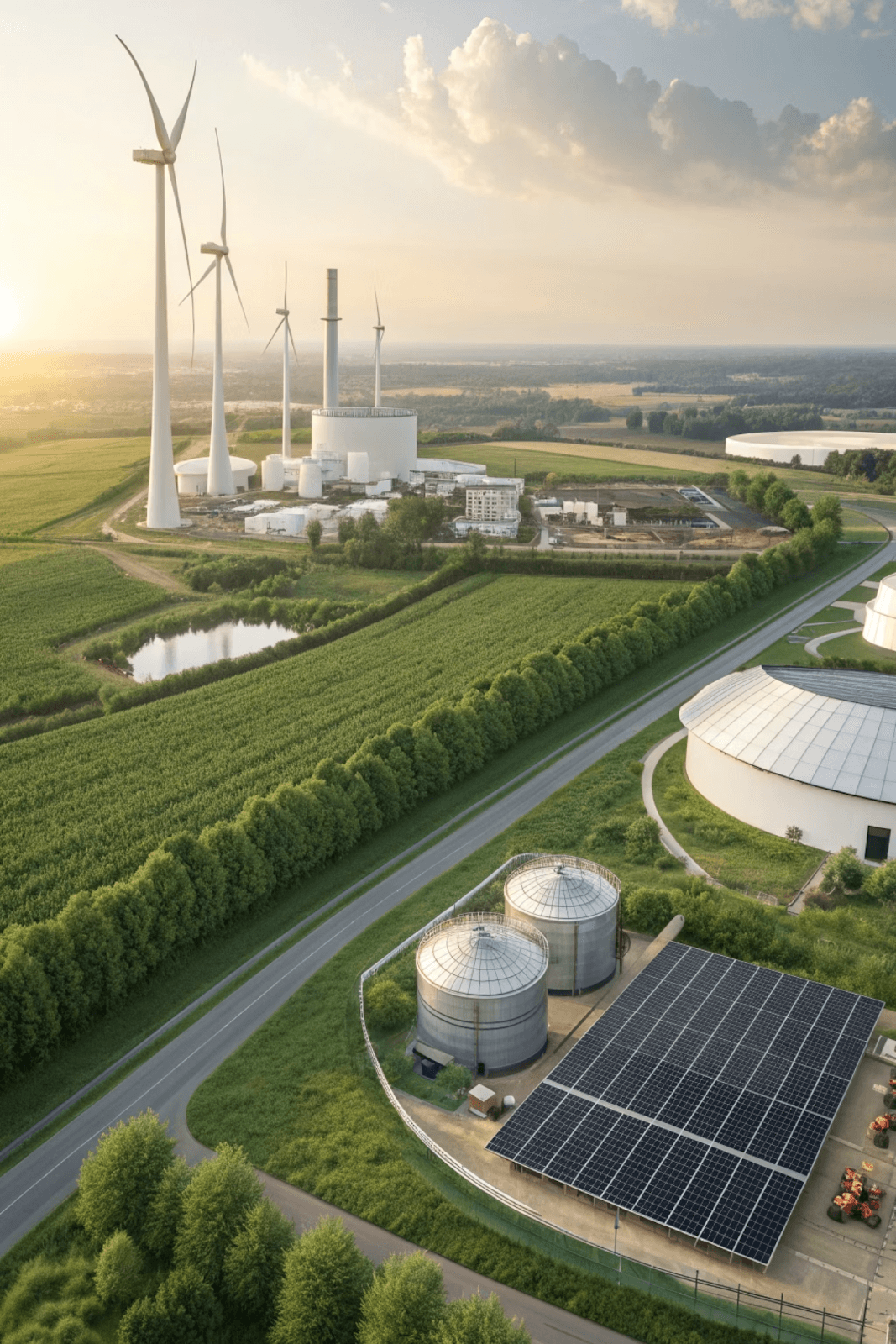

Green & Sustainable

Eco-friendly production with zero toxic chemicals

Safe & Certified

100% heavy metal-free, independently tested

Circular Economy

Built to last 15+ years, fully recyclable

Redefining Industry Standards

We do this by redefining industry standards. Every Dima Handle pull carries this promise to our partners: technical excellence, environmental respect, and guaranteed profitability. While competitors compromise on the details, we elevate them.

Technical Excellence

Patented aerospace-grade components and PVDuv coating technology

Environmental Respect

Zero toxic chemicals, minimal waste, maximum durability

Guaranteed Profitability

Lifetime warranty, consistent quality, decisive competitive advantage

Driss Massanou and his team have developed this technology to offer you a decisive competitive advantage. Our partners don't just sell handles – they sell the future of the industry.

Join Us

We position ourselves as the partner brand for 'green, safe, sustainable, circular' hardware, offering a single product that meets all tastes and ensures our partners can complete their production with a healthy and reliable accessory.

Partner with Innovation

Join a brand that's revolutionizing the hardware industry from the inside out

Gain Competitive Edge

Offer your customers the only truly sustainable, certified hardware solution

Build the Future

Be part of the movement that proves true sustainability is in the details

True sustainability is in the details. And the details are what set Dima Handle apart.